110kv Steel Electrical Transmission Tower With Double Circuit Arm

Reference Specification

| Power Voltage |

10 KV ~550 KV |

| Type |

Steel Pole |

| Design Load in Kg |

300~ 1000 Kg appliced to 50cm from the to pole |

| Material |

Steel |

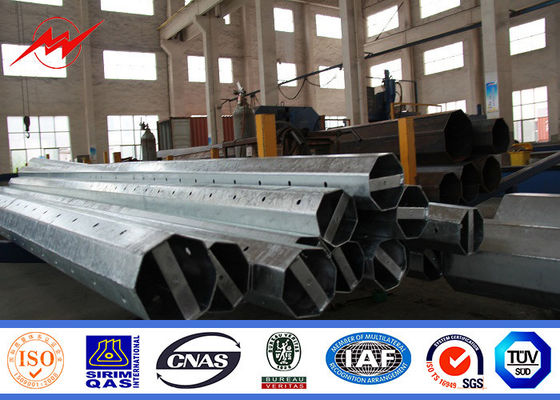

| Production Process |

Raw material test → Cutting→Molding or bending →Welding (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Packaging |

| Thickness |

1 mm to 30 mm |

| Welding |

Welding complies with CSA and AWS, AWS D1.1 standard.

The welders have got corresponding certificate after testing and inspection. |

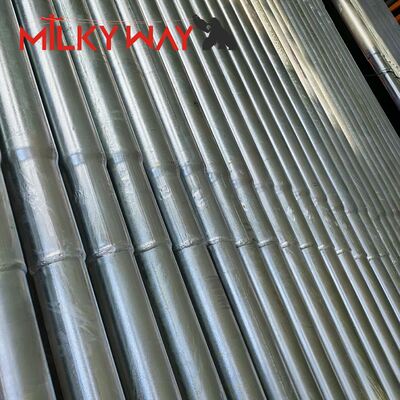

| Galvanizing |

Hot dip galvanization in accordance with Chinese standard GB/T 13912-2002

or American standard ASTM A123. |

| Design of pole |

We can design free of charge if Qty is numerous, client should supply the design parameter. |

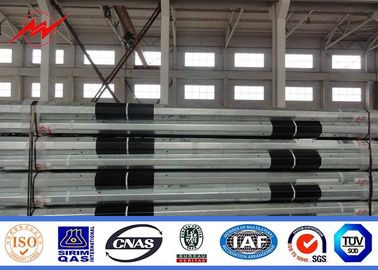

Factory

Estabilsed in 1991,Jiangsu Milky Way Steel Poles is located in Wuxi,East of China ,near one of the largest sea port of China ,Shanghai,Port .

Our Products have been widely used in the power transmsion ,signal transmission and ligting for street ,road ,square ,palaestra.and so on

We have plenty of export experience . Since our first overseas order from Pakstan in 1991 of 132 KV transmission poels ,our products have been deliveried to more than 70 contries and areas ,including America,Australia ,Russia ,Genmery ,Span,Philippines ,Malaysia and so on

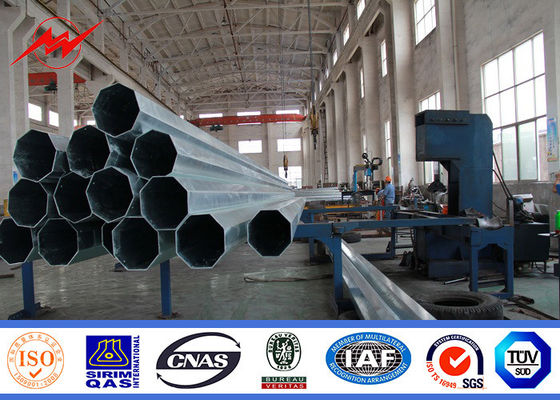

Our factory owns advanced production lines and machines including bending calibration machine, hydraulic plate shears machine, shears machine, slitting machine, 208T hydraulic straightener, etc. All the purpose is to produce good quality steel poles.

The fabrication process as cutting plate, bending, forming, automatic welding, drill holes, quality checked before galvanized, hot dip galvanized and powder coating, finally quality checked according to client's requirements.

Production process

Raw material test → Cutting →Molding or bending →Welidng (longitudinal )→Dimension verify →Flange welding →Hole drilling →Calibration → Deburr→Galvanization or powder coating ,painting →Recalibration →Thread →Package

Why Choose us?

* Tower Design tailor made to your requirements

* Pre Dispatch inspection by buyer or international inspection agency.

* Steel certified as per international.

* Design of Tower as per China/ International design standards.

* Galvanization as per international standard.

* Timely project completion.

* Convenient transportation to Qingdao port & airport(only one hour)

* We are manufacturer. We have our own land & factory. The land was bought instead of renting.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!