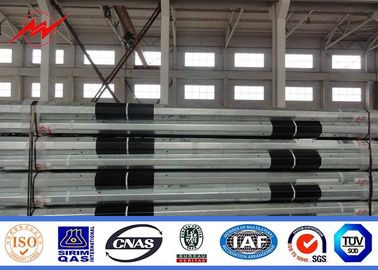

Bitumen Galvanized Electrical Power Pole With Circuit Breaker Switch

Mechanical Property

The metal supports are designed to withstand the nominal force F and the pressure of the wind V

applied at 0.25m from the top. Under these loads, the safety factor with respect to the elastic limit of the

steel is larger than 1.8. The post also resists a torque equal to (F+V) ×1m. Tests shows the load intervened

when breaking is around 2 times of design load.

| Welding |

Standard |

Standard Title |

|

Pole shafts&multi-sided tubular

Cross arms&all accessories

|

AWS D1.1/D1.1M:2010 |

Structural Welding Code-Steel |

| Welding wire |

AWS D1.1/D1.1M:2010 |

Structural Welding Code-Steel |

Steel

The material is in accordance with NF EN 10025 standard and NF EN 10149 standard, it has the

following property.

- Yield Strength=355 N/mm2

- Thoughness remains the same under 20 degrees below zero

- Galvanization is in accordance with NFA35503 standard class I

Maintenance

The hot dip galvanization treatment can increase the service life of the steel pole without the

environmental pollution and no need for other daily maintenance. The following described types

are specially designed for Africa Market which can meet the regulated height and load standard

of France electricity power company.

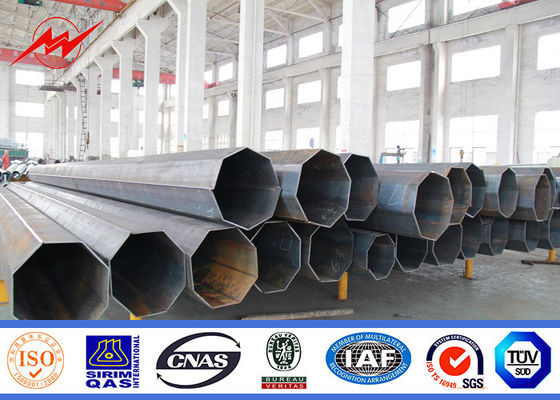

Production

Our steel pole is bent to form to the polygonal (conical) section firstly. Then it is welded by the

automatic submerged-arc. Then it is welded by the automatic submerged-arc welding machine.

Thirdly the top cap, strip and base plate will be welded to the pole. And finally other accessories

(support brackets, ladder support, etc.) will be welded to the pole shaft.

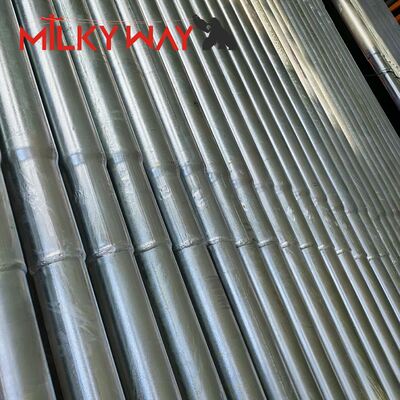

Galvanization

The galvanization of the steel pole are under strict control. Galvanization is achieved by immersion

in a molten zinc bath(450̊) after pre-treated (dipping).

Mechanical Property

The metal supports are designed to withstand the nominal force F and the pressure of the wind V

applied at 0.25m from the top. Under these loads, the safety factor with respect to the elastic limit

of the steel is larger than 1.8. The post also resists a torque equal to (F+V) ×1m. Tests shows the

load intervened when breaking is around 2 times of design load.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!